Teamwork makes the dream work

Here’s a glimpse of the amazing team behind all of our major successes. At Innoseis ST, we believe that teamwork is the secret to success.

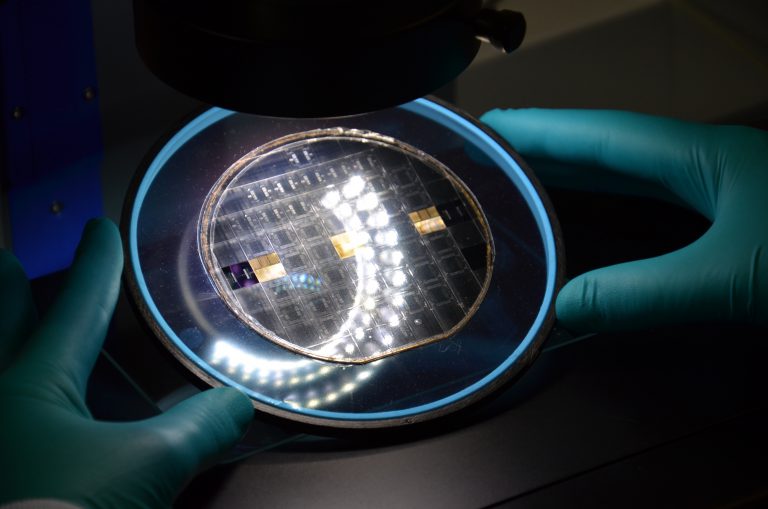

Introducing the worlds smallest, most sensitive microelectromechanical systems accelerometers, engineered with high performance and low power consumption at its heart.

These MEMS sensors are built to power tomorrow’s navigation, guidance, and measurement systems.

Unrivaled sensitivity and stability with a bandwidth from 0 to 200 Hz gives your application ultra-precise data.

Competitive per-unit costs through standardised, volume production manufacturing.

Industry-leading ultra low-power consumption as low as 20mW offers efficient solutions.

At 9x9x3mm and only 1.5 grams, our sensors are the smallest and lightest MEMS sensors of this class on the market today.

Innoseis Sensor Technology MEMS sensors were born from fundamental research into gravitational wave detection and are now demonstrating world-record performance in their class, addressing critical needs in various application areas.

Leveraging in-house experience, we’re developing the next generation of novel sensing products, designing and manufacturing high precision, low power wireless sensing technology, improving clients’ business and operational efficiencies.

Improved orbit and propulsion control for longer operational lifetimes.

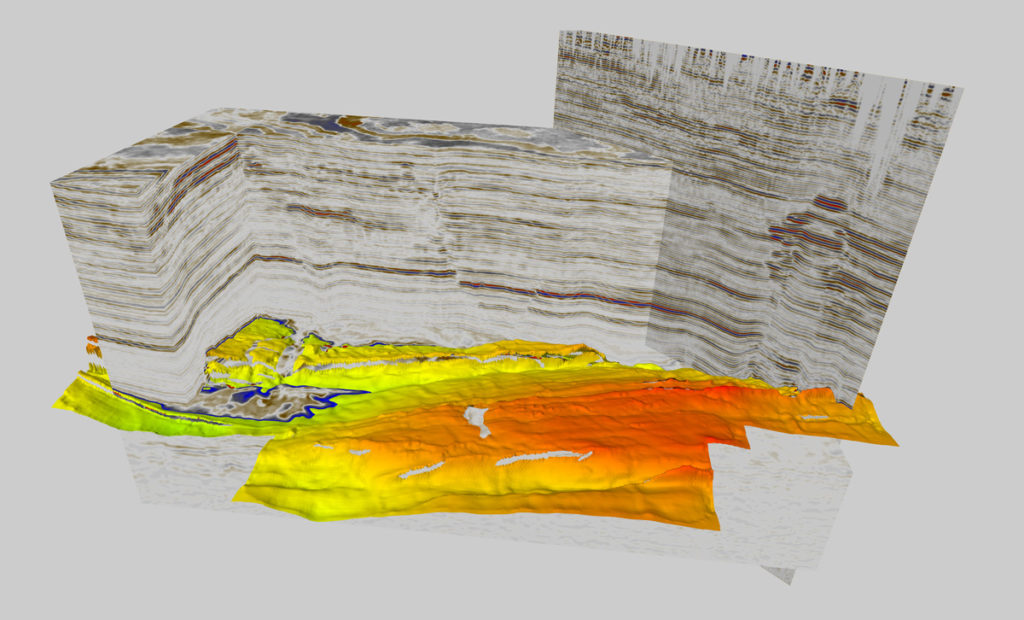

Better quality seismic signals with lower operational cost.

High precision positioning, with or without GPS assist.

Fast identification of changes to structural integrity.

Here’s a glimpse of the amazing team behind all of our major successes. At Innoseis ST, we believe that teamwork is the secret to success.

Upon celebrating our 10 year milestone, it’s appropriate to acknowledge IXA’s role in the Innoseis journey. IXA has been a key partner, offering invaluable guidance

First and foremost we’d like to congratulate NIKHEF on completing their renovation at Amsterdam Science Park. It has been the utmost pleasure to work in

Copyright © 2022 Innoseis Sensor Technologies